The Cessna 152 Service Manual is a comprehensive guide for maintaining and repairing the aircraft. It provides detailed procedures, safety protocols, and technical specifications to ensure optimal performance and compliance with aviation standards.

1.1 Overview of the Cessna 152 Aircraft

The Cessna 152 is a two-seat, single-engine aircraft widely used for flight training and personal flying. Known for its reliability and fuel efficiency, it features a Lycoming O-235 engine, producing 110 horsepower. With a maximum cruise speed of 110 knots and a range of approximately 435 nautical miles, the Cessna 152 is ideal for training and short-distance flights. Its durable design and forgiving handling make it a popular choice for student pilots. The aircraft’s simple systems and robust construction contribute to its low maintenance costs. The Cessna 152 service manual plays a crucial role in ensuring the aircraft remains airworthy by providing detailed maintenance procedures. This manual is essential for owners, mechanics, and pilots to understand the aircraft’s systems, specifications, and operational limits, ensuring safety and performance.

1.2 Importance of the Service Manual

The Cessna 152 Service Manual is indispensable for ensuring the aircraft’s airworthiness, safety, and optimal performance. It provides detailed maintenance procedures, troubleshooting guides, and compliance requirements, making it a critical resource for owners, mechanics, and pilots. By following the manual, users can adhere to FAA regulations, prevent potential issues, and extend the aircraft’s service life. The manual also serves as a reference for understanding the aircraft’s systems, specifications, and limitations. Regular updates and service bulletins ensure compliance with the latest aviation standards. Without the service manual, maintaining the Cessna 152 would be challenging and risky, potentially leading to safety hazards and non-compliance with legal requirements. Its importance cannot be overstated, as it is the cornerstone of responsible aircraft ownership and operation.

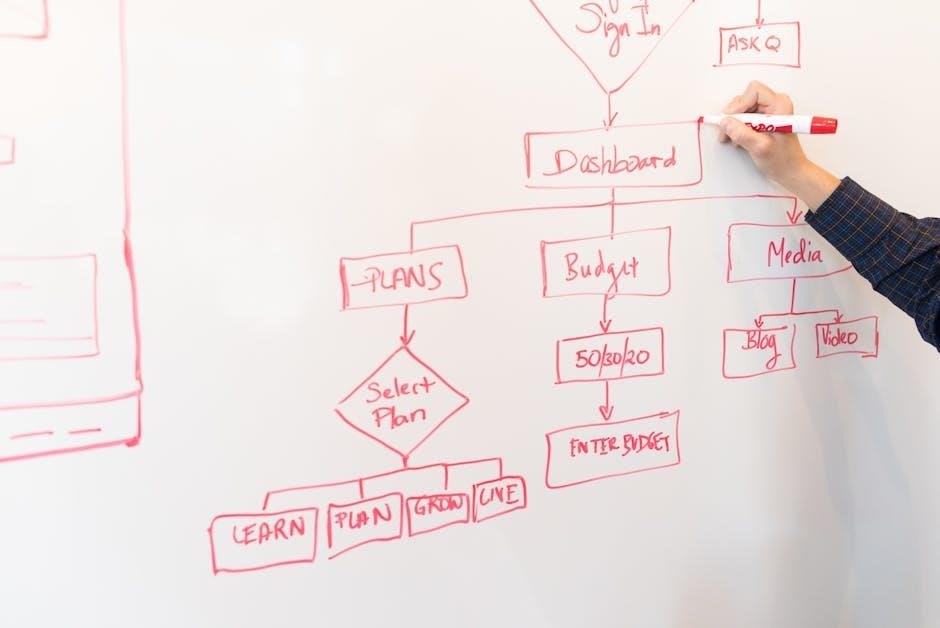

1.3 Structure and Content of the Manual

The Cessna 152 Service Manual is organized into clear sections for easy navigation. It begins with introductory information and safety precautions, followed by detailed technical specifications and aircraft limitations. The manual then outlines maintenance schedules, routine tasks, and troubleshooting procedures. Additional sections cover engine and propeller maintenance, airframe inspections, and avionics upgrades. It also addresses legal compliance, including FAA regulations and record-keeping requirements. The manual is supplemented with diagrams, charts, and reference materials to aid in understanding complex procedures. Each chapter is designed to provide precise instructions, ensuring that users can perform tasks efficiently and safely. The structured format makes it an essential tool for both experienced mechanics and novice owners, covering all aspects of aircraft maintenance and operation. This comprehensive approach ensures that the manual is a complete resource for the Cessna 152.

Key Sections of the Cessna 152 Service Manual

The Cessna 152 Service Manual includes key sections on safety, specifications, maintenance schedules, and legal compliance, ensuring comprehensive guidance for aircraft upkeep and operation, essential for mechanics and owners.

The Cessna 152 Service Manual begins with an introduction that outlines the purpose and scope of the document. It emphasizes the importance of adhering to safety protocols to ensure the well-being of personnel and the integrity of the aircraft. Safety information is detailed, including warnings, cautions, and notes that highlight critical procedures and potential hazards. This section serves as a foundation for understanding the manual’s structure and content, providing essential guidelines for safe and effective maintenance practices. Proper adherence to these safety measures is crucial to prevent accidents and maintain compliance with regulatory standards.

2.2 Aircraft Specifications and Limitations

The Cessna 152 Service Manual provides detailed specifications and limitations for the aircraft, ensuring safe and efficient operation. Key details include maximum takeoff weight, fuel capacity, and operational limits. The manual specifies the aircraft’s performance parameters, such as climb rates, cruising speeds, and service ceilings. It also outlines environmental limits, including temperature ranges and altitude restrictions. Additionally, the document lists critical system specifications, such as oil capacities, tire pressures, and battery requirements. Adherence to these specifications is essential for maintaining airworthiness and ensuring the aircraft operates within its designed capabilities. The manual also references service bulletins and airworthiness directives to address potential issues and upgrades, ensuring compliance with regulatory standards. This section is vital for pilots, mechanics, and owners to understand the aircraft’s capabilities and operational boundaries.

2.3 Maintenance Schedules and Intervals

The Cessna 152 Service Manual outlines detailed maintenance schedules and intervals to ensure the aircraft remains airworthy. Routine inspections are required at specific flight hour intervals, with tasks escalating in complexity. Pre-flight checks, daily inspections, and periodic maintenance tasks are clearly defined. Annual inspections and 100-hour inspections are mandatory, covering engine, propeller, and airframe components. Lubrication intervals, tire pressure checks, and battery maintenance schedules are also specified. Compliance with these schedules is critical to prevent wear and tear, ensuring safety and optimal performance. The manual provides timelines for parts replacement and overhaul, such as engine inspections every 100 hours. Adhering to these intervals guarantees the aircraft operates within its design limits, reducing the risk of mechanical failures. Proper record-keeping of maintenance activities is essential for regulatory compliance and long-term reliability of the aircraft.

Maintenance Procedures

The Cessna 152 Service Manual provides detailed procedures for inspections, routine tasks, and troubleshooting. It ensures safe and efficient maintenance, covering pre-flight, post-flight, and periodic checks for optimal aircraft performance.

3.1 Pre-Flight and Post-Flight Inspections

The Cessna 152 Service Manual outlines detailed procedures for pre-flight and post-flight inspections to ensure aircraft safety and performance. These checks cover critical systems, including control surfaces, tires, brakes, and fuel levels. Pilots must verify all instruments are functioning correctly and address any discrepancies immediately. Post-flight inspections involve securing the aircraft, checking for damage, and documenting any issues for maintenance. Regular inspections help prevent mechanical failures and extend the aircraft’s service life. Adhering to these protocols is essential for maintaining airworthiness and complying with aviation regulations. The manual provides a checklist to guide pilots through each step, ensuring thoroughness and consistency. Proper inspection practices are vital for safe operations and protecting the investment in the aircraft.

3.2 Routine Maintenance Tasks

Routine maintenance tasks for the Cessna 152 are essential to ensure the aircraft remains airworthy and operates efficiently. These tasks include oil changes, tire pressure checks, and battery maintenance. The service manual provides specific intervals for these procedures to prevent mechanical failures. Regular lubrication of moving parts and inspection of control surfaces are also critical. Additionally, the manual outlines procedures for cleaning and servicing the fuel system to avoid contamination. Adherence to these routines ensures safety and extends the aircraft’s lifespan. Proper documentation of all maintenance activities is required for compliance with aviation regulations. By following the guidelines in the Cessna 152 Service Manual, owners and mechanics can maintain the aircraft’s performance and reliability.

3.3 Troubleshooting Common Issues

The Cessna 152 Service Manual provides detailed troubleshooting guides for common issues, ensuring prompt resolution and minimal downtime. Engine performance problems, such as rough running or lack of power, are addressed through diagnostic steps like carburetor adjustments and compression checks. Electrical system malfunctions, including faulty avionics or lighting, are resolved by testing circuits and replacing components as needed. Landing gear issues, like improper retraction, are corrected through hydraulic system checks and actuator maintenance. The manual emphasizes the importance of thorough pre-flight inspections and logbook reviews to identify potential problems early. By following the troubleshooting procedures, mechanics can efficiently repair issues, ensuring the aircraft remains airworthy and safe for operation. Regular adherence to these guidelines helps prevent recurring problems and maintains the overall reliability of the Cessna 152.

Engine and Propeller Maintenance

The Cessna 152 Service Manual details engine inspection, overhaul, and propeller maintenance. Regular inspections and timely overhauls ensure optimal performance and safety, adhering to manufacturer guidelines and regulatory standards.

4.1 Engine Inspection and Overhaul

The Cessna 152 Service Manual outlines detailed procedures for engine inspection and overhaul. Regular inspections, including pre-flight checks and 50-hour inspections, ensure early detection of wear and tear. The manual specifies intervals for compression tests, cylinder condition assessments, and oil analysis to monitor engine health. Major overhauls involve disassembling the engine, inspecting components like piston rings and valves, and replacing parts as needed. Compliance with FAA regulations and manufacturer guidelines is emphasized to maintain airworthiness. Proper documentation of all inspections and overhauls is required, ensuring traceability and adherence to safety standards. Certified mechanics are recommended to perform complex procedures to guarantee reliability and performance. This section is critical for extending the engine’s service life and preventing unforeseen failures during flight operations.

4.2 Propeller Maintenance and Repair

Propeller maintenance is crucial for ensuring the Cessna 152’s performance and safety. The service manual details regular inspection procedures, including blade condition checks for nicks, dents, or corrosion. Hub assembly lubrication and pitch control mechanism tests are also outlined. Repair guidelines specify when to address minor damage or imbalance. Balancing the propeller is required if vibrations exceed acceptable levels. The manual recommends using approved repair facilities for complex issues. Additionally, it emphasizes adherence to manufacturer specifications for blade replacement and hub overhauls. Proper documentation of all maintenance activities is mandatory. Regular propeller upkeep ensures smooth operation, reduces wear on connected systems, and prevents potential failures. Mechanics are advised to follow these procedures meticulously to maintain the aircraft’s airworthiness and reliability;

4.3 Fuel System Servicing

Fuel system servicing is a critical aspect of maintaining the Cessna 152’s airworthiness. The service manual provides detailed steps for inspecting fuel tanks, lines, and fittings for leaks, corrosion, or blockages. It outlines procedures for draining fuel samples to check for contamination or water ingress. Cleaning and replacing fuel filters is emphasized, along with testing fuel pumps and pressure systems. The manual also covers recalibration of fuel quantity indicators and addressing issues related to fuel flow. Proper handling and disposal of hazardous materials are stressed. Additionally, it recommends periodic testing of the fuel system’s integrity to ensure reliability. By following these guidelines, mechanics can prevent fuel-related malfunctions and ensure the aircraft operates safely and efficiently at all altitudes and conditions.

Airframe and Avionics Maintenance

Airframe inspection involves checking structural integrity, while avionics maintenance ensures system functionality. The manual provides guidelines for troubleshooting and adhering to service bulletins for optimal performance and safety.

5.1 Airframe Inspection and Repair

The Cessna 152 Service Manual outlines detailed airframe inspection and repair procedures to ensure structural integrity and safety. Regular inspections are required to identify and address wear, corrosion, or damage to components such as wings, fuselage, and control surfaces. The manual provides guidelines for visual checks, tooling, and repair techniques. Specific attention is given to high-stress areas like rivets, bolts, and seams. Repairs must comply with FAA standards and use approved materials. Additionally, the manual includes diagrams and step-by-step instructions for replacing damaged parts and reinforcing weakened structures. Proper documentation of all inspections and repairs is emphasized to maintain airworthiness. Adherence to these procedures ensures the aircraft remains safe and operational, minimizing downtime and extending service life.

5;2 Avionics System Upgrades and Maintenance

The Cessna 152 Service Manual provides detailed guidance on avionics system upgrades and maintenance to ensure optimal performance and compliance with modern aviation standards. Regular checks of communication, navigation, and instrumentation systems are essential to prevent malfunctions. The manual outlines procedures for inspecting and calibrating avionics components, such as radios, GPS units, and transponders. Upgrades, like installing modern glass cockpit systems, are also covered, with instructions for integrating new hardware and software. Troubleshooting common avionics issues, such as static interference or faulty displays, is addressed with step-by-step solutions. Additionally, the manual emphasizes the importance of adhering to FAA guidelines when modifying or upgrading avionics systems. Proper documentation of all maintenance and upgrades is required to maintain airworthiness. These procedures ensure the aircraft remains reliable and meets current regulatory requirements for safe operation.

5.3 Electrical System Troubleshooting

Troubleshooting the electrical system of the Cessna 152 is critical for ensuring reliable operation. The service manual provides detailed procedures for identifying and resolving common electrical issues, such as faulty circuit breakers, wiring malfunctions, or battery failures. Regular inspections of electrical connectors, fuses, and ground wires are essential to prevent system malfunctions. The manual also outlines steps for diagnosing intermittent electrical faults, which can be challenging to identify. Additionally, it covers proper techniques for testing voltage and current flow using multimeters and other diagnostic tools. Addressing electrical issues promptly is vital to avoid more severe problems, such as system failures during flight. By following the troubleshooting guidelines, mechanics can restore the electrical system to optimal functionality, ensuring safe and efficient aircraft operation. Proper documentation of all repairs and inspections is also emphasized to maintain compliance with maintenance records.

Legal and Regulatory Compliance

This section covers essential FAA regulations, airworthiness directives, service bulletins, and mandatory modifications to ensure legal compliance and safe operation of the Cessna 152 aircraft.

6.1 FAA Regulations and Airworthiness Directives

Compliance with FAA regulations is critical for the safe operation of the Cessna 152. The service manual outlines airworthiness directives, ensuring adherence to federal aviation standards. These directives often mandate specific inspections, repairs, or replacements to maintain the aircraft’s airworthiness. For instance, Temporary Revision Number 6, dated April 01, 2012, highlights essential modifications and inspections required for compliance. Failure to comply can result in the aircraft being deemed unairworthy. The manual also provides guidance on documenting completed directives and ensuring all maintenance aligns with FAA requirements. Regular reviews of service bulletins and letters are crucial to stay updated on the latest regulatory changes. By following these guidelines, owners and mechanics can ensure the Cessna 152 operates safely and legally.

6.2 Service Bulletins and Mandatory Modifications

Service bulletins and mandatory modifications are critical for ensuring the Cessna 152 remains airworthy and compliant with safety standards. These bulletins, issued by the manufacturer and approved by the FAA, address specific components or systems requiring attention. Mandatory modifications are legally required and must be implemented within a specified timeframe. The service manual lists 15 service bulletins, including Temporary Revision Number 6 (dated April 01, 2012), which outlines essential inspections and repairs. Non-compliance with these directives can result in the loss of airworthiness certification. Owners and mechanics must review and implement these modifications promptly, documenting all actions for regulatory oversight. Regular updates and adherence to these bulletins ensure the aircraft’s safety and performance are maintained at the highest level.

6.3 Record-Keeping and Documentation

Proper record-keeping and documentation are essential for maintaining compliance and tracking the maintenance history of the Cessna 152. The service manual emphasizes the importance of detailed and accurate records, including all inspections, repairs, and modifications. These records must be stored securely and made available for review by regulatory authorities. Each entry should include the date, description of work performed, and the technician’s certification. Additionally, documentation of compliance with service bulletins and airworthiness directives is mandatory. Proper record-keeping ensures traceability and accountability, crucial for maintaining the aircraft’s airworthiness and resale value. Failure to maintain adequate records can lead to legal and operational consequences. The service manual provides specific guidelines for documenting maintenance activities, ensuring clarity and consistency in record-keeping practices for owners and mechanics.

Resources for Cessna 152 Owners and Mechanics

Owners and mechanics can access the Cessna 152 Service Manual PDF through official Cessna websites or trusted aviation maintenance platforms. Additional resources include aviation forums, repair organizations, and FAA-approved service centers for guidance and support.

7.1 Where to Download the Cessna 152 Service Manual PDF

The Cessna 152 Service Manual PDF can be downloaded from official Cessna websites, aviation maintenance platforms, or trusted retailers like ATP or Aircraft Spruce. Ensure you use authorized sources to avoid unauthorized or outdated versions. Additionally, many aviation communities and forums provide links to verified PDFs, but always verify the source’s credibility. Some owners also share scanned copies through specialized groups, but caution is advised to comply with copyright and legal standards. Official distributors often require registration or payment for access, ensuring authenticity and compliance with aviation regulations. Always cross-check the manual’s revision date and number to guarantee you have the latest updates for accurate maintenance procedures.

7.2 Trusted Sources for Service Manuals

Trusted sources for the Cessna 152 Service Manual include official Cessna websites, authorized aviation parts suppliers, and reputable aircraft maintenance organizations. Platforms like ATP (Aircraft Technical Publishers) and Aircraft Spruce specialize in providing authentic maintenance documents. Additionally, the FAA website often hosts or links to essential service manuals and airworthiness directives. Many aviation schools and training centers also offer access to these manuals as part of their educational resources. Online forums and communities, such as those dedicated to Cessna owners, may share verified links or recommend reliable distributors. Always verify the credibility of the source to ensure the manual is genuine and up-to-date. Purchasing directly from Cessna or its authorized dealers guarantees authenticity and compliance with aviation standards.

7.3 Online Communities and Forums

Online communities and forums are invaluable resources for Cessna 152 owners and mechanics. Platforms like the Cessna Owner Organization and AOPA forums host discussions on maintenance, troubleshooting, and service manual access. Many users share their experiences, offering tips on where to find genuine service manuals and how to interpret complex procedures. These forums often include links to trusted sources for downloading the Cessna 152 Service Manual PDF. Additionally, specialized aviation forums discuss modifications, upgrades, and common issues, providing a wealth of knowledge. Some communities also archive service bulletins and technical documentation, making them a one-stop resource for maintenance needs. Engaging with these forums can help users connect with experienced mechanics and pilots, ensuring compliance with safety standards and best practices. They are a vital support network for anyone working on the Cessna 152.

Accessories and Tools

The Cessna 152 Service Manual highlights essential tools and accessories for maintenance. These include specialized wrenches, diagnostic equipment, and safety gear. Trusted sources and manufacturer recommendations ensure reliability and compliance with aviation standards;

8.1 Essential Tools for Maintenance

The Cessna 152 Service Manual outlines essential tools required for effective maintenance. These include wrenches, pliers, screwdrivers, and diagnostic equipment. Safety gear like gloves and goggles is also recommended. The manual emphasizes using manufacturer-approved tools to ensure precision and reliability. Proper tool selection prevents damage to aircraft components and guarantees compliance with safety standards. Additionally, the manual provides guidance on tool storage and organization to streamline maintenance processes. Regular tool inspections are advised to maintain their effectiveness. By adhering to these recommendations, mechanics can perform tasks efficiently and safely, ensuring the aircraft remains airworthy. The manual also lists trusted suppliers for procurement, making it easier to acquire the necessary tools. Proper tool usage is critical for extending the aircraft’s service life and maintaining operational integrity.

8.2 Recommended Upgrades and Modifications

The Cessna 152 Service Manual suggests several upgrades and modifications to enhance performance, safety, and comfort. Popular upgrades include avionics improvements, such as installing modern GPS systems or ADS-B technology, to meet current aviation standards. Engine enhancements, like high-performance air filters or fuel injection systems, can improve fuel efficiency and power. Propeller modifications, such as switching to a constant-speed propeller, can boost takeoff and climb performance. Additionally, aerodynamic upgrades like wingtip extensions or fairings can reduce drag and improve efficiency. Interior upgrades, such as new seating or lighting, can enhance comfort and functionality. Safety modifications, like emergency landing gear or advanced weather radar, are also recommended. These upgrades not only improve the aircraft’s capabilities but also increase its value and operational reliability. Always consult the service manual for compatibility and compliance before making any modifications.