Carburetor tuning involves adjusting air-fuel mixtures for optimal engine performance. Proper tuning enhances fuel efficiency, power delivery, and engine longevity. This guide covers essential steps and expert tips for precise adjustments, ensuring smooth operation across all RPM ranges.

1.1 Overview of Carburetor Tuning

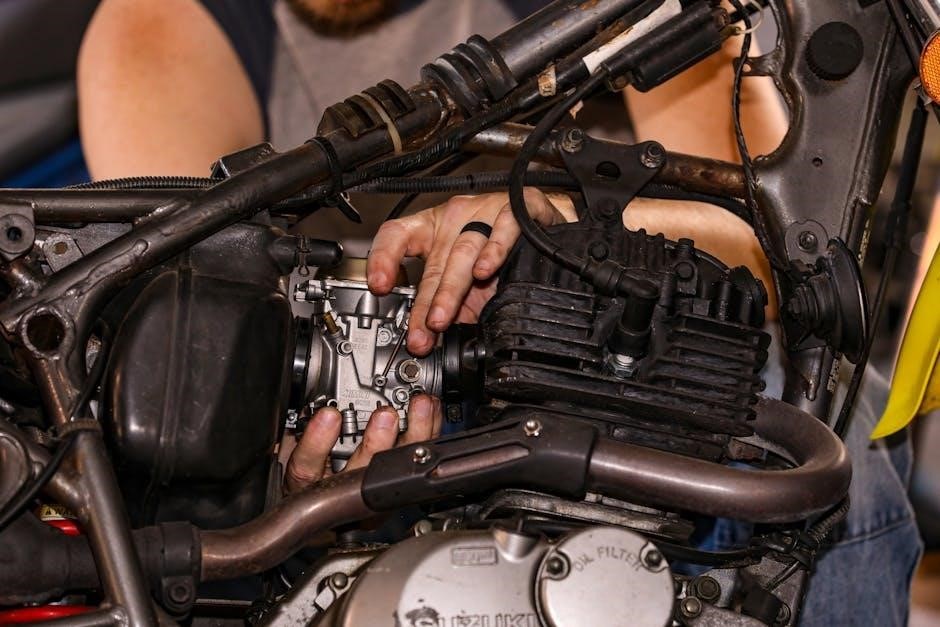

Carburetor tuning is the process of adjusting the air-fuel mixture to optimize engine performance; It involves fine-tuning circuits like idle, midrange, and main jets to ensure proper fuel delivery at all RPM levels. Tuning begins with synchronizing carbs and setting baseline adjustments. Tools like screwdrivers and jetting gauges are essential. Experts recommend starting with stock settings for a reliable baseline. Adjustments are made by modifying needle positions, jet sizes, and mixture screws. Proper tuning enhances power, efficiency, and engine longevity. This guide provides step-by-step instructions and expert tips for achieving the perfect balance in your carburetor setup.

1.2 Importance of Proper Carburetor Tuning

Proper carburetor tuning is crucial for optimal engine performance, fuel efficiency, and longevity. A well-tuned carburetor ensures the correct air-fuel mixture at all RPM levels, preventing issues like surging, hesitation, or poor idle. Incorrect tuning can lead to decreased performance, reduced fuel efficiency, and potential engine damage. Tuning also enhances throttle response, making the engine run smoother and more reliably. Additionally, proper tuning reduces emissions and ensures the engine operates within its designed parameters. Regular tuning is essential, especially after modifications or changes in operating conditions. A correctly tuned carburetor delivers peak power, efficiency, and reliability, making it a cornerstone of engine maintenance.

Essential Components of a Carburetor

A carburetor’s essential components include the pilot circuit, needle, main jet, idle speed screw, and float level. Each part plays a vital role in air-fuel mixture regulation.

2.1 Definition and Function of a Carburetor

A carburetor is a device that mixes air and fuel in the correct proportion for internal combustion engines. It operates by using the venturi effect to create a pressure drop, drawing fuel into the airflow. The throttle valve regulates airflow, while jets and needles control fuel delivery. The carburetor ensures the optimal air-fuel mixture is supplied to the engine cylinders, enabling efficient combustion. Proper function is critical for engine performance, fuel efficiency, and smooth operation across various RPM ranges. Understanding its operation is key to effective tuning and maintenance.

2.2 Key Parts of a Carburetor

A carburetor consists of several critical components essential for its operation. The throttle valve regulates airflow, while the venturi creates a pressure drop to draw fuel. The float bowl stores fuel, and the float maintains the fuel level. Jets (pilot, needle, and main) deliver fuel at specific engine speeds. The needle adjusts the fuel mixture in the midrange, and the idle mixture screw fine-tunes low-RPM fuel flow. These parts work together to ensure the correct air-fuel mixture is delivered to the engine, enabling efficient combustion and optimal performance.

Preparation for Carburetor Tuning

Ensure proper tools like screwdrivers, jetting kits, and synchronization tools are ready. Sync multiple carbs, set baseline adjustments, and verify valve clearances before tuning begins for accuracy.

3.1 Tools and Materials Needed

To begin carburetor tuning, gather essential tools: a flathead screwdriver for adjusting idle screws, a Phillips screwdriver for mixture screws, and a jetting kit for main and pilot jets. A vacuum gauge is crucial for synchronizing multiple carbs, ensuring balanced airflow. Additionally, a torque wrench and pliers may be needed for removing carburetor components. Keep a jetting calculator handy for precise jet sizing based on engine modifications. Cleaning supplies like carburetor cleaner and a soft brush are necessary for maintenance. Always consult the factory service manual for specific tools and ensure valve clearances are within specifications before tuning begins.

3.2 Synchronizing Multiple Carburetors

Synchronizing multiple carburetors ensures balanced airflow and fuel delivery across all cylinders. Start by warming the engine to operating temperature. Use a vacuum gauge to measure intake manifold vacuum from each carburetor. Adjust the synchronization screws or linkage to equalize the readings; Proper synchronization prevents issues like hesitation, surging, or uneven power delivery. If equipped, consult the factory manual for specific procedures. Ensure all carbs are set to the same baseline adjustments before synchronizing. This step is critical for engines with multiple carbs, as imbalance can lead to poor performance and decreased efficiency. Regular checks and adjustments maintain optimal engine operation.

3.3 Setting the Baseline Adjustments

Setting baseline adjustments is crucial for a well-tuned carburetor. Begin by referring to the factory service manual for stock settings. Ensure the engine is at operating temperature before making adjustments. Start with the idle speed screw, turning it clockwise to increase RPM and counterclockwise to decrease. Adjust the idle mixture screws by turning them in until the engine almost stalls, then back out 1-2 turns for a smooth idle. Synchronize multiple carbs using a vacuum gauge to ensure balanced airflow. Document all changes for future reference. Proper baseline settings provide a foundation for further tuning, ensuring reliable engine performance and efficiency.

Idle Circuit Tuning

Idle circuit tuning focuses on adjusting the idle speed and mixture screws for smooth low-RPM operation. Proper settings ensure consistent engine idle and quick throttle response.

4.1 Adjusting the Idle Speed Screw

Adjusting the idle speed screw is crucial for achieving a smooth engine idle. Start by bringing the engine to operating temperature. Locate the idle speed screw on the carburetor and turn it clockwise to increase RPM or counterclockwise to decrease it. Fine-tune the screw until the engine runs steadily without surging. Ensure the idle mixture is balanced for optimal performance. Proper adjustment prevents stalling and ensures smooth throttle response. Always refer to the factory specifications for precise settings. This step lays the foundation for overall carburetor tuning, ensuring reliable engine operation at low speeds.

4.2 Fine-Tuning the Idle Mixture

Fine-tuning the idle mixture ensures a smooth, efficient engine operation at low RPM. Start by locating the idle mixture screws on the carburetor. Turn the screws clockwise to lean the mixture or counterclockwise to enrich it. Begin with the screws fully in, then back them out 1-2 turns. Test the engine’s response, adjusting for a steady idle without surging or sputtering. Proper adjustment ensures optimal fuel delivery, preventing stalls and improving low-speed performance. This step is critical for achieving a balanced air-fuel mixture, essential for reliable engine operation and overall efficiency.

4.3 Common Issues and Solutions

Common issues during idle tuning include surging, hesitation, or stalling. These often result from an improper air-fuel mixture. If the engine surges or hesitates, the mixture may be too lean, requiring the idle mixture screws to be turned counterclockwise. Conversely, if the engine sputters or bogs, the mixture is too rich, and the screws should be turned clockwise. Additionally, ensure the idle speed screw is properly adjusted for a steady RPM. Always check for vacuum leaks and worn components, as these can disrupt idle performance. Regular maintenance, such as cleaning the carburetor and inspecting the air filter, can prevent these issues from arising.

Midrange Circuit Tuning

The midrange circuit, active between 1/4 to 3/4 throttle, is controlled by the needle position. Adjustments here optimize performance, addressing surging or sputtering issues for smooth power delivery.

5.1 Understanding the Midrange Circuit

The midrange circuit operates between 1/4 to 3/4 throttle, delivering fuel during moderate engine loads. It relies on the needle’s position to regulate airflow and fuel flow. Proper adjustment ensures smooth power delivery, preventing surging or bogging. The needle’s taper and height influence the air-fuel mixture, with higher positions enriching the mixture and lower positions leaning it. Tuning this circuit requires careful observation of engine behavior, such as hesitation or sputtering, to determine if adjustments are needed. This critical range directly impacts rideability and performance, making precise tuning essential for optimal engine operation.

5.2 Adjusting the Needle Position

Adjusting the needle position fine-tunes the midrange circuit’s air-fuel mixture. Raise the needle (lower the clip) if the engine surges or hesitates, indicating a lean condition. Lower the needle (raise the clip) if sputtering or bogging occurs, signaling a rich mixture. Test at steady throttle between 1/4 and 3/4 openings. Small adjustments, one notch at a time, allow precise calibration. Always ride and observe engine behavior before making further changes. Documenting adjustments helps track progress and ensures optimal performance across the midrange. This step is crucial for smooth power delivery and responsive throttle response.

5.3 Identifying and Correcting Midrange Problems

Midrange issues, such as surging or hesitation, indicate a lean air-fuel mixture, while sputtering or bogging suggests a rich condition. To correct these, adjust the needle position based on throttle response. If surging occurs, raise the needle (lower the clip) to enrich the mixture. For sputtering, lower the needle (raise the clip) to reduce fuel flow. Test adjustments at steady throttle between 1/4 and 3/4 openings. Document changes to track progress and ensure consistent performance. Proper correction ensures smooth power delivery and eliminates midrange sluggishness, optimizing engine efficiency and responsiveness.

Main Jet Tuning

Main jet tuning optimizes fuel flow at higher RPMs. Determine the correct size based on engine performance and test after installation to ensure proper air-fuel mixture and efficiency.

6.1 Role of the Main Jet in Carburetor Function

The main jet plays a crucial role in carburetor function by regulating fuel flow during high engine speeds. It ensures the correct air-fuel mixture is delivered when the throttle is fully open, preventing lean or rich conditions. Properly sized main jets are essential for optimal performance, as they directly impact power output and engine efficiency. Incorrect sizing can lead to issues like hesitation or reduced power, emphasizing the importance of precise selection and installation. Regular testing and adjustments are necessary to maintain peak performance and prevent potential engine damage from improper fueling.

6.2 Determining the Correct Main Jet Size

Determining the correct main jet size involves a combination of baseline settings and performance testing. Start with the factory-recommended jet size, then synchronize the carbs and set baseline adjustments. Test the engine at full throttle to observe performance. If the engine hesitates or sputters, the jet is too small; if it runs rich or loses power, the jet is too large. Fine-tune by incrementally changing jet sizes and retesting. Using a jetting calculator can provide precise recommendations based on engine modifications and operating conditions. Proper jet sizing ensures optimal fuel flow, maximizing power and efficiency while preventing engine damage from lean or rich conditions.

6.3 Installing and Testing the Main Jet

Installing the main jet requires removing the carburetor bowl and carefully replacing the jet. Once installed, test the engine at full throttle to assess performance. If the engine hesitates or sputters, the jet may be too small. If it runs rich or loses power, the jet is too large. Fine-tune by incrementally adjusting jet sizes and retesting. Ensure proper synchronization of multiple carbs and verify baseline adjustments before final testing. Use a jetting calculator for precise recommendations based on engine modifications. Proper installation and testing ensure optimal fuel flow, maximizing power and efficiency while preventing engine damage from lean or rich conditions.

Advanced Carburetor Tuning Techniques

Advanced tuning involves optimizing air-fuel ratios, fine-tuning for engine modifications, and using jetting calculators for precision. These techniques ensure peak performance and efficiency across all RPM ranges.

7.1 Air-Fuel Ratio Optimization

Air-fuel ratio optimization is critical for maximizing engine performance and efficiency. A stoichiometric ratio of 14.7:1 is ideal for most engines, but adjustments may be needed based on specific modifications or operating conditions. Richer mixtures (lower air-fuel ratios) can enhance power at high RPMs, while leaner mixtures improve fuel efficiency. Using a jetting calculator or dyno testing helps achieve precise ratios. Regular spark plug inspections provide visual feedback on mixture accuracy, ensuring optimal combustion and minimizing engine damage. Proper optimization reduces emissions and enhances overall engine reliability.

7.2 Fine-Tuning for Specific Engine Modifications

Fine-tuning a carburetor for modified engines requires precise adjustments to match performance needs. Aftermarket components like high-performance intake systems or cams often demand richer or leaner fuel mixtures. Jet sizes, needle positions, and float levels may need customization to ensure proper fuel delivery. Tools like jetting calculators help determine ideal settings based on engine specs and modifications. Testing under various loads and conditions is essential to refine adjustments. Regular monitoring of spark plugs and engine behavior provides feedback for further tweaks. Proper tuning enhances power output, efficiency, and reliability, ensuring the engine operates at its best with the given modifications.

7.3 Using a Jetting Calculator for Precision

A jetting calculator is a valuable tool for achieving precise carburetor tuning. By inputting engine specifications, such as displacement, compression ratio, and camshaft details, the calculator provides optimized jetting recommendations. This method reduces trial and error, ensuring the correct air-fuel mixture for peak performance. While traditional tuning relies on experience, a jetting calculator offers a data-driven approach, tailored to specific engine modifications. It’s especially useful for heavily modified engines, where stock settings may not suffice. Regular updates and adjustments based on calculator inputs help maintain optimal performance, making it an essential resource for both novice and experienced tuners.

Troubleshooting Common Carburetor Issues

Troubleshooting carburetor issues involves identifying symptoms like surging, hesitation, or bogging. Common problems include incorrect jetting, faulty floats, or clogged circuits. Cleaning, adjusting, or replacing components often resolves these issues.

8.1 Diagnosing Lean and Rich Conditions

Diagnosing lean and rich conditions is crucial for optimal carburetor performance. A lean condition occurs when there’s too much air relative to fuel, causing surging or hesitation. A rich condition, with too much fuel, leads to sputtering or bogging. Symptoms of a lean mixture include a clean or white spark plug, while a rich mixture results in a sooty or black plug. Adjustments to the needle position or jet size can correct these imbalances. Always check valve clearances and synchronize carbs before tuning to ensure accurate diagnostics and effective adjustments for smooth engine operation.

8.2 Addressing Hesitation and Surging

Hesitation and surging are common issues during midrange operation. Hesitation occurs when the engine briefly stalls under throttle, often due to a lean mixture. Surging happens when excess fuel causes an uneven power delivery. To address these, adjust the needle position: lower the needle for richness or raise it for leanness. Ride at a steady throttle between 1/4 and 3/4 openings to identify issues. If surging persists, check the air filter and ensure proper carb synchronization. Gradual adjustments and testing are key to achieving smooth power delivery without over-correcting the mixture.

8.3 Fixing Bogging and Sputtering

Bogging and sputtering are typically caused by an overly rich fuel mixture or improper float levels. Bogging occurs when excess fuel floods the engine under acceleration, while sputtering indicates a lean condition or fuel starvation. To fix these issues, start by checking the float level and ensuring it’s within specifications. Next, adjust the needle position to richness or leanness as needed. Clean or replace the pilot jet if clogged, as this can disrupt fuel flow. Test the bike under load to identify improvements. Gradual adjustments and thorough testing are crucial to eliminate these issues and restore smooth throttle response.

Maintenance Tips for Carburetors

Regular cleaning, inspecting float levels, and replacing worn parts ensure optimal performance. Clean the carburetor with a solvent and inspect for cracks or damage. Replace faulty components promptly to maintain proper fuel flow and engine efficiency.

9.1 Cleaning the Carburetor

Cleaning the carburetor is essential for maintaining proper fuel flow and engine performance. Start by disconnecting the fuel line and removing the float bowl. Use a carburetor cleaning solvent to soak and scrub all components, paying attention to small passages and jets. Avoid using harsh chemicals that could damage rubber or plastic parts. After cleaning, dry all components thoroughly with compressed air. Reassemble the carburetor, ensuring all gaskets and seals are in good condition. A clean carburetor ensures accurate fuel delivery, preventing issues like rough idling or poor acceleration. Regular cleaning helps maintain optimal engine operation and longevity.

9.2 Replacing Worn or Damaged Parts

Replacing worn or damaged carburetor parts is crucial for maintaining optimal performance. Inspect components like gaskets, seals, and jets for wear or damage. Use original or high-quality replacement parts to ensure proper fit and function. Replace any cracked or worn intake manifolds and O-rings to prevent air leaks. Damaged float needles or seats should be replaced to avoid fuel leaks or inconsistent fuel levels. After replacing parts, carefully reassemble the carburetor, ensuring all connections are secure. Proper synchronization of multiple carbs is essential for smooth engine operation. Regular replacement of worn parts prevents performance issues and ensures reliable engine function over time;

9.3 Regular Inspection and Adjustment

Regular inspection and adjustment are vital for maintaining optimal carburetor performance. Check for worn gaskets, seals, and jets, and clean or replace them as needed. Inspect the float bowl for debris and ensure proper fuel flow. Adjust the idle mixture screws periodically to maintain the correct air-fuel ratio. Synchronize multiple carbs to ensure smooth engine operation. Clean the carburetor thoroughly, especially after riding in dusty conditions. Refer to the factory service manual for specific adjustment procedures. Regular maintenance prevents issues like hesitation, surging, or poor idle. By staying proactive, you can ensure your carburetor operates efficiently and delivers consistent engine performance over time.

Proper carburetor tuning is essential for optimal engine performance, efficiency, and longevity. This guide provides a comprehensive approach to tuning, from basics to advanced techniques, ensuring peak power delivery and smooth operation across all conditions.

10.1 Summary of Key Tuning Steps

Effective carburetor tuning involves several critical steps. Start by synchronizing multiple carbs and setting baseline adjustments. Adjust the idle speed and mixture screws for smooth low-RPM operation. For midrange tuning, modify the needle position based on throttle response. Install and test the main jet to ensure proper fuel flow at high RPM. Use a jetting calculator for precision and fine-tune for specific engine modifications. Regularly inspect and clean the carburetor, replacing worn parts as needed. Document all changes and test the engine under various conditions to ensure optimal performance. Consistent maintenance and adjustments will maximize efficiency and power output.

10.2 Final Tips for Optimal Performance

For optimal carburetor performance, always synchronize multiple carbs and ensure proper valve clearances. Use a jetting calculator for precise adjustments and test under various conditions. Adjust idle screws for smooth operation and fine-tune the float level within specifications. Regularly clean and inspect the carburetor, replacing worn parts promptly. Document all changes to track performance improvements. Avoid over-richening the mixture, as it can reduce efficiency. Fine-tune the needle position for midrange responsiveness and ensure the main jet size matches engine demands. By following these steps, you’ll achieve a well-balanced air-fuel mixture, enhancing power, efficiency, and overall engine reliability.